SmartFix4.0 from Forms & Gears/ASM is the smartest way to transform your existing fixture/workholding in to intelligent, IoT enabled, Industry 4.0 fixtures/workholdings. Talk to our experts and know how you can increase your productivity with lesser manpower.

Call us now at +91 7823962010.

Forms and Gears, Asia's leading fixture builder, has been on the forefront of fixture building technology for over 47 years. Now Forms and Gears’ fixture building expertise, in partnership with ASM Technologies's IT, Data Analytics and Artificial Intelligence strengths, brings you SmartFix4.0 - a revolution in fixture building and work-holding.

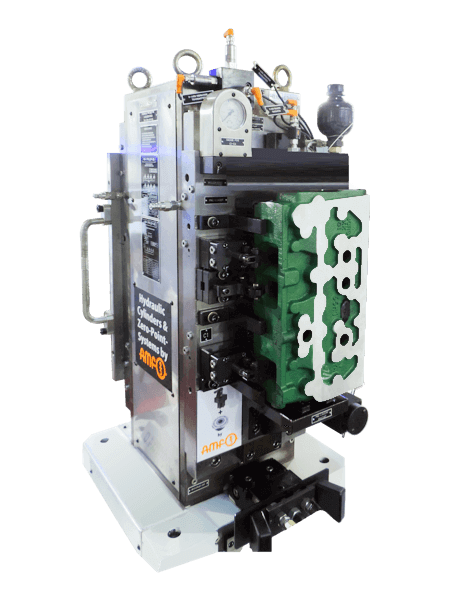

SmartFix4.0 is a precision work-holding device with the ability to collect, transmit and analyse data in a useful format to the end user. Developed for the first in the world, SmartFix4.0 takes the world of work-holding and fixtures into Industry 4.0 standard, without replacing the existing fixture or workholding. And that’s really a revolution.

Can be mounted on existing fixtures

Industry 4.0 compliant and IoT ready

Cloud-based application

Graphical data visualizations

Multiple sensor data visualization

Threshold breach indicators

Tool wear analytics

Cost per component analytics

Vibration Alerts

Declamp alerts

Output of Fixture and machine

Predictive maintenance of fixture and machine

Operator efficiency analytics

Historical performance analysis of machine, powerpack, tools and fixture

Powerpack oil level and oil contamination alerts

Analytics which are easy to understand reports

Insights that save cost and improve efficiency

In-depth cost analysis makes costing realistic

Tool wear analytics to optimise consumable costs.

Highly cost-effective as it enables intelligence on existing fixtures

Predictive maintenance ensures long life of machines and tools

Want to make your fixtures and workholdings smarter?

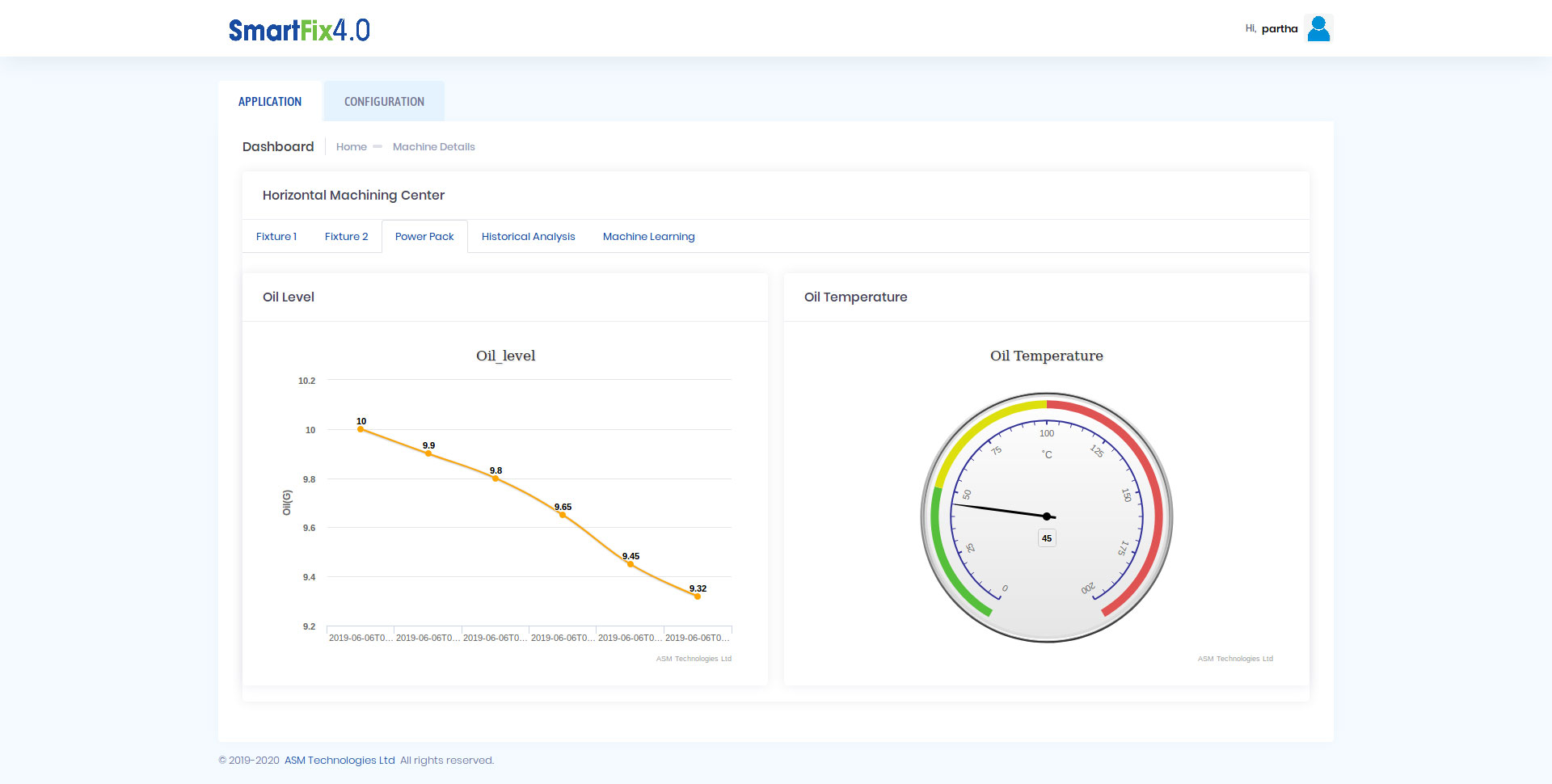

GET A FREE QUOTEAs the fixture is in continuous contact with the component it is the ideal device to collect and analyse data at a component level. Sensors to monitor vibration, pressure, and component sensing are mounted on the fixture. And sensors to monitor oil levels and temperature are mounted on the powerpack.

The high volume of data collected from these sensors are continuously transmitted wirelessly to the cloud where it is parsed and stored for analysis.

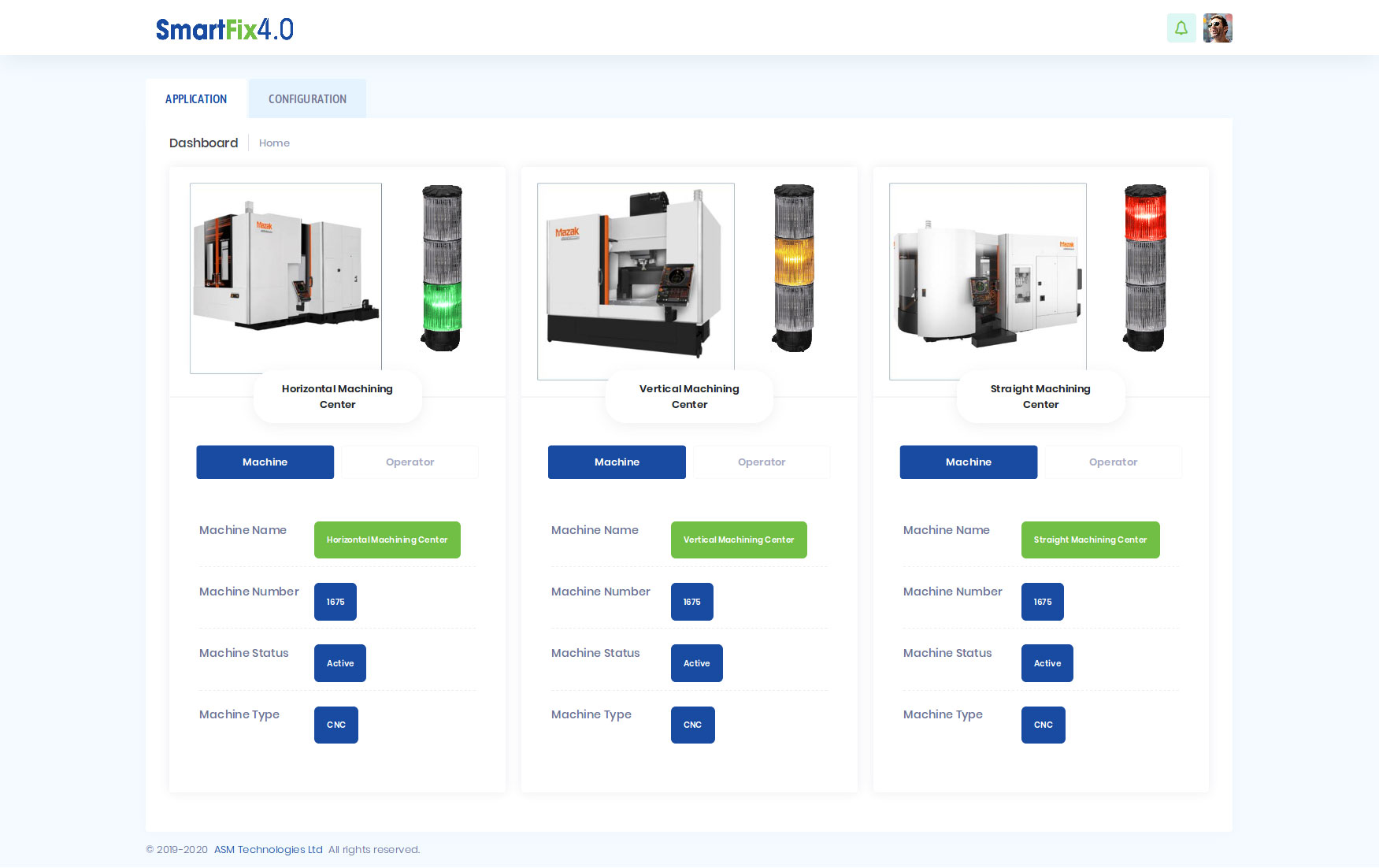

The raw data is then analysed using Data Analytic and Artificial Intelligence tools and sent back to a custom built Dashboard of the end user, that resembles their factory floor, showing all the machines in action as well as a quick summary on the health of each machine, fixture and powerpack.

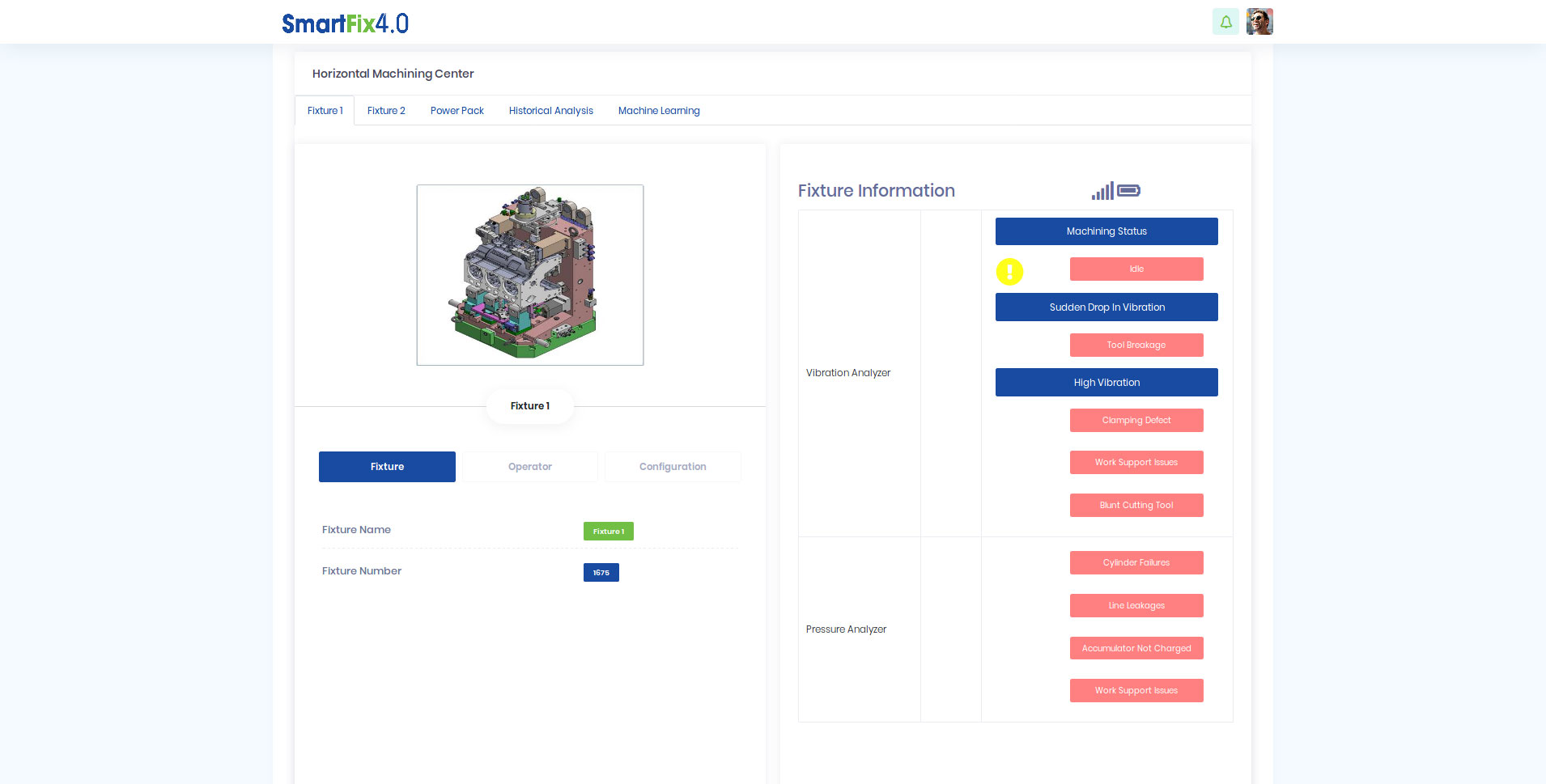

The user can click on each machine to get a more detailed understanding of the analysed data per fixture. Data per sensor is visualized graphically with an ability to go back and see historical performance of the machine with this fixture.

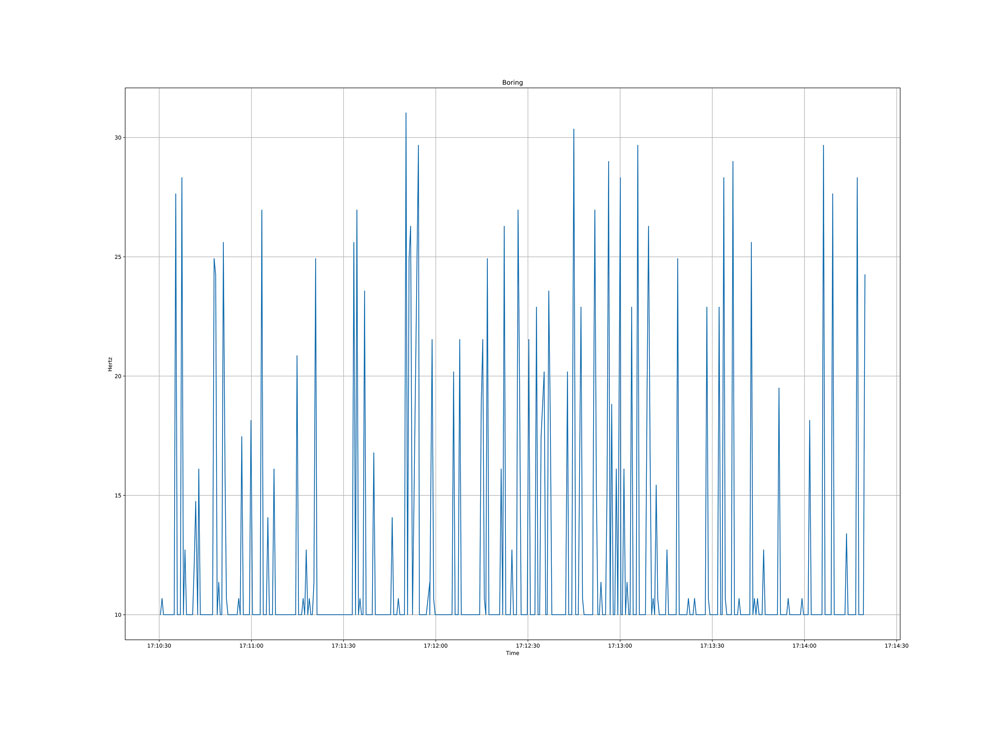

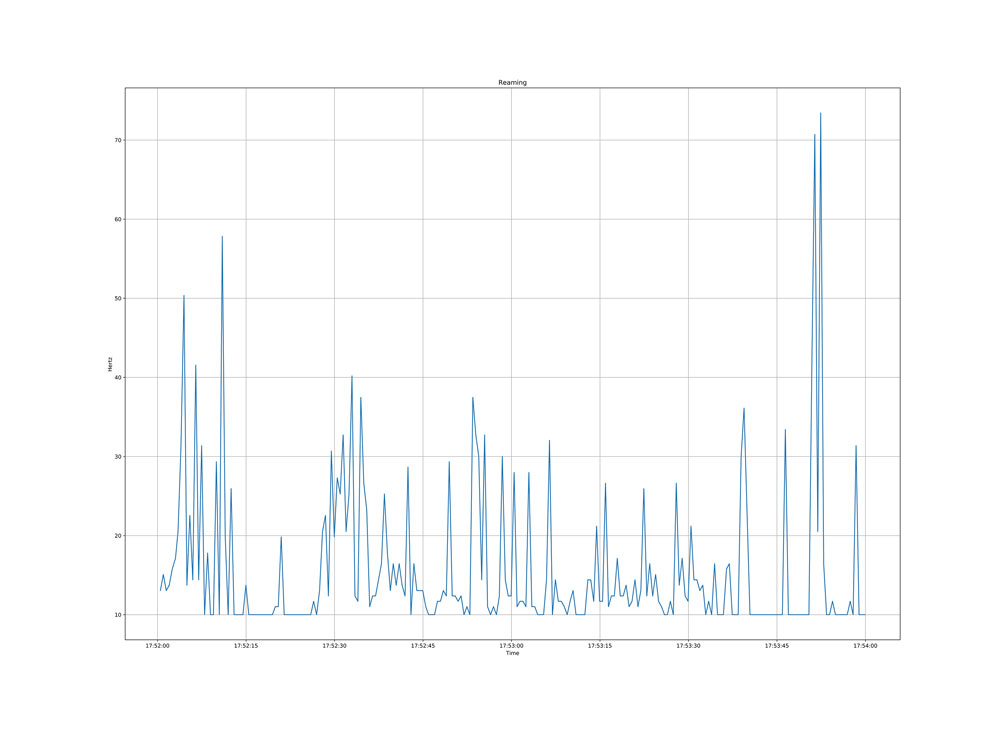

For example, an analysis of data collected from vibration could reveal a wide variety of information like casting tolerances, vibration level comparison between tools and vibration comparison across machines in the plant. This real time data could result in productivity increases, optimising tool life and increasing safety.

If the vibration crosses a set upper threshold limit the system can be designed to shut the machine off remotely through the emergency switch of the machine.

Sensors to monitor pressure would alert the operator via their phone or on any smart device and this can again be linked to the machine emergency switch if required to ensure that in case of a sudden pressure drop the machine is switched off.

By monitoring the clamp / decamp cycles, alerts for maintainence of fixtures, ordering of spares and seal kits would also be automatically generated by the system and alerts sent via smart phone to the concerned people.

With Artificial Intelligence and Machine Learning, SmartFix 4.0 can also help the user to be more proactive on machine, tool and fixture performance as well as how machines are performing compared to each other.

Historical data can be analysed and a comparison of various parameters can be made across all machines in the plant giving the management useful information to reduce costs, increase efficiencies and improve quality.

Status of all your Machines

Fixture State and Machine Alerts

Sensor Values and Analysis

Power Pack Status and Analysis

Industry Pioaneer in Fixture Level AI

Analytics is tailor made case-by-case to solve unique problems and work in all kinds of situations.

Leverage Machine Learning and Artificial Intelligence (ML/AI) to provide a wide range of benefits.

Machine Learning models constantly improve with more data to generate best outcome.

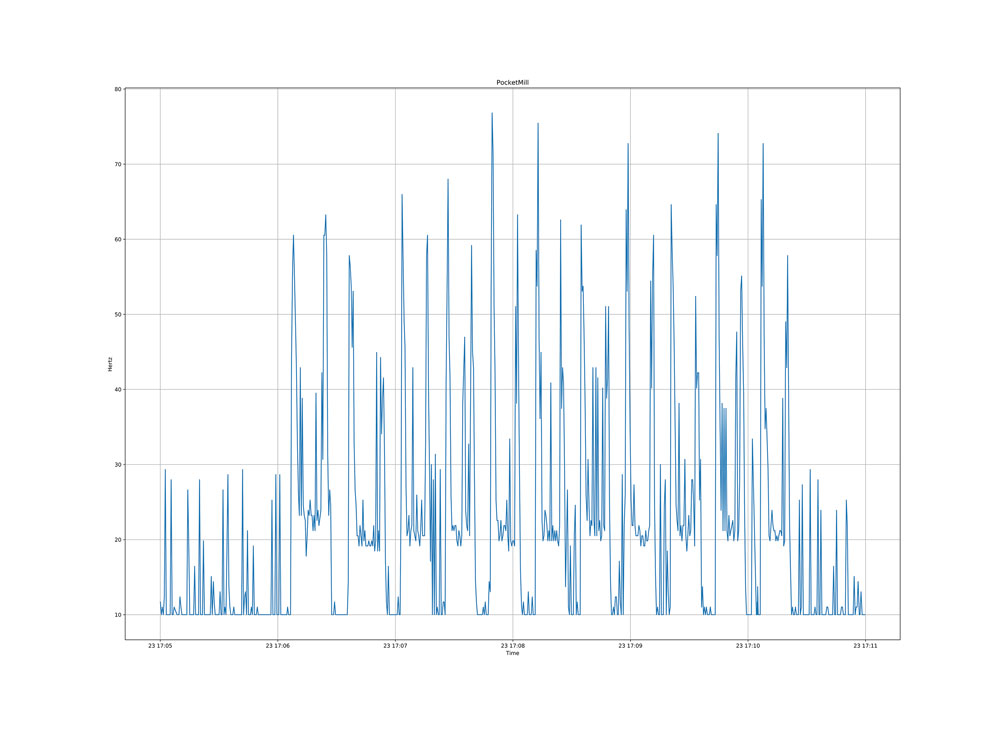

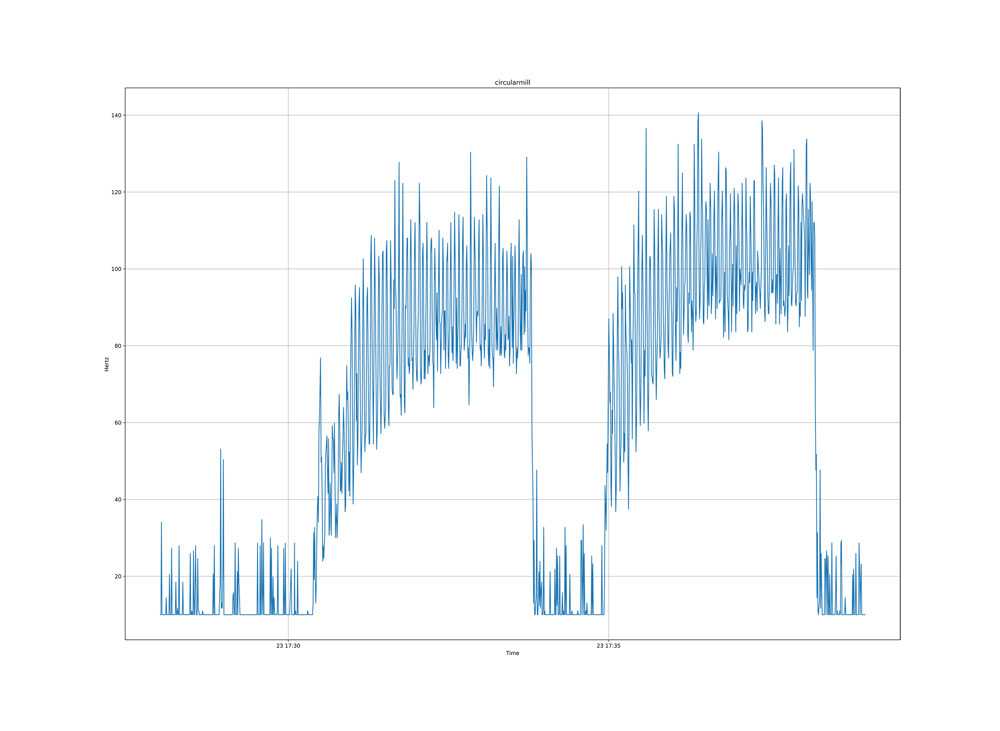

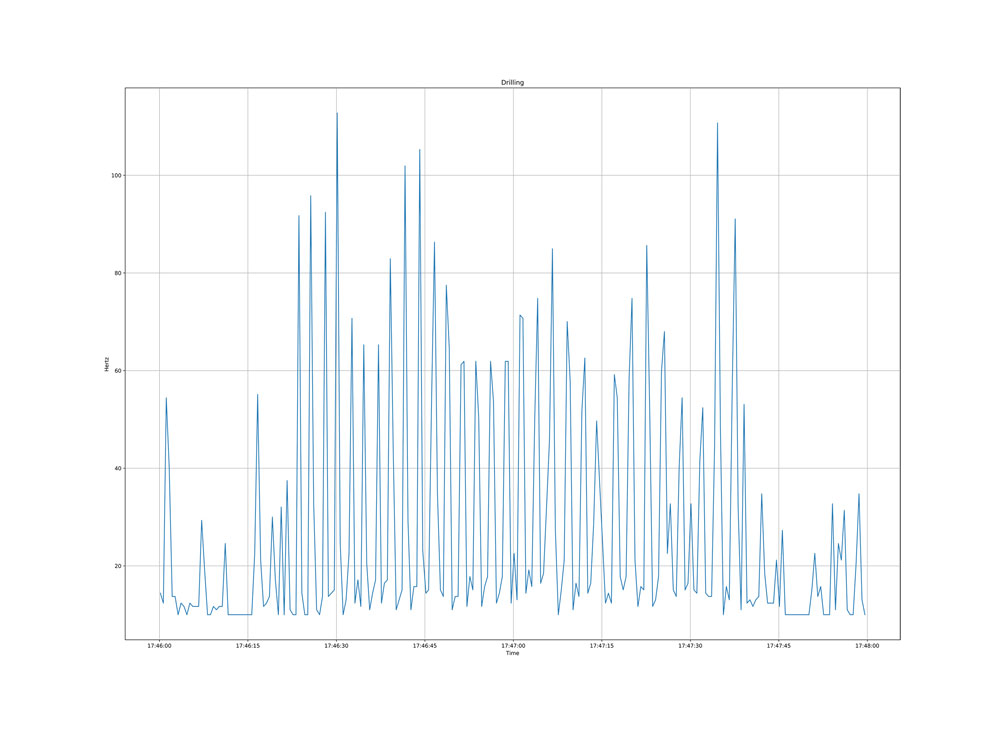

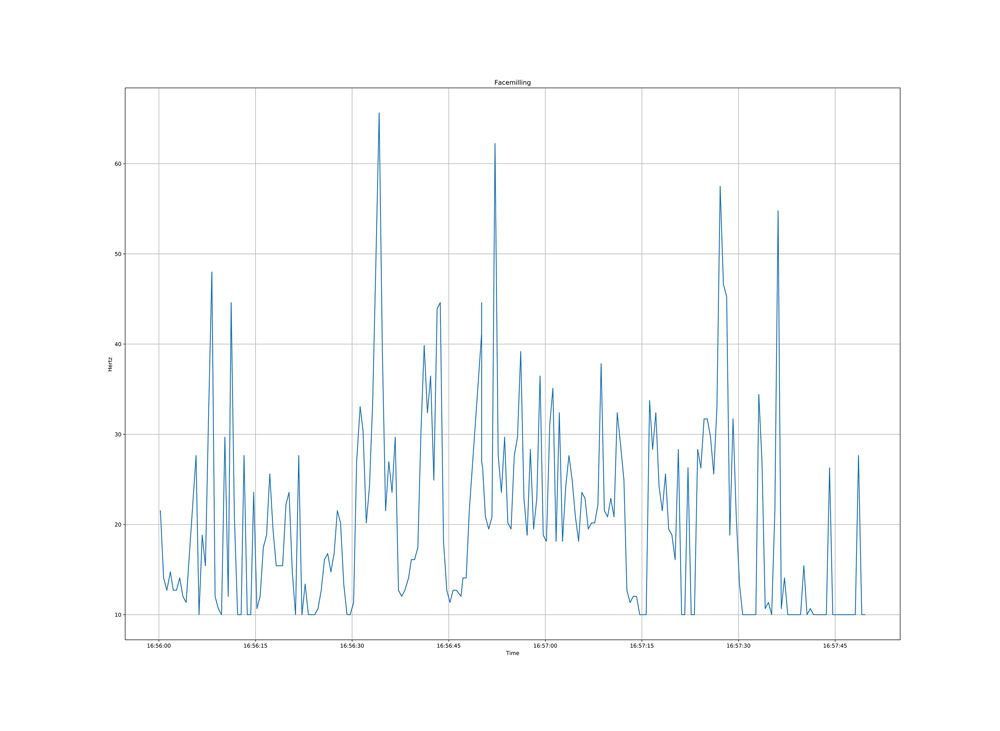

The unique vibration patterns from each and every machining operation are analyzed using AI & ML to predict tool wear

Estimate cost per component per tool

Cost saving in tool consumption

Pocket Milling Operation

Circular Milling Operation

Drilling Operation

Face Milling Operation

Boring Operation

Reaming Operation

Presence in 7 countries

5 decades’ experience in fixture building

Expert development team

Trusted by world’s best companies

Please write to us or call us. We are always happy to help.

Enquire

Lorem ipsum dolor sit amet consectetur adipisicing elit. Expedita ex minima voluptate quam similique officia quibusdam voluptates non rerum soluta possimus beatae dolorem dolor magni recusandae, sequi, fugiat mollitia maiores.

Lorem ipsum, dolor sit amet consectetur adipisicing elit. Doloremque iste, molestias dolor modi maiores sapiente, eaque blanditiis harum et excepturi ipsa quidem deserunt cumque recusandae? Saepe recusandae deserunt assumenda culpa?

Lorem ipsum dolor sit amet consectetur adipisicing elit. Ratione, laborum error id expedita provident culpa enim molestias aperiam quisquam repellat magnam corporis, mollitia est suscipit, nihil quam atque recusandae saepe.

Akhil Rabindra

An ASM/RV Forms & Gears team member and Race Car Driver - Aston Martin Racing Driver Academy racing in the Aston Martin GT4 Vantage at the, GT4 European Series 2019 and 24H Series European (GT) 2019.